We offer following services

- Application Engineering

- New Product Development & Chemistry

- Process & Product Design

- Thermal Management

- Sound & Vibration Control

- Temporary Surface protection

- Surface Treatment & Coating

- Rust & Corrosion Management

How We Benefits Industry Sectors at All Stages

Design Stage

During the design phase, we help OEMs identify suitable chemicals that will enhance their product’s functionality, safety, and durability. This includes selecting appropriate lubricants, adhesives, and coatings that support high performance and meet regulatory standards.

Production Stage

In the production phase, we ensure the smooth integration of selected chemicals, advising on chemical compatibility, application techniques, and waste management. This minimizes potential issues like corrosion, material degradation, or safety hazards.

Maintenance & Life Cycle Management

Proper maintenance requires the right chemical solutions for cleaning, protection, and repair. we offer guidance on chemical products that prolong the life cycle of equipment, enhance safety, and reduce environmental risks.

1-Electronics and Technology Industry

Thermal Management Solutions: Electronics generate significant heat, especially in devices designed for speed and efficiency. We guide companies in selecting the best thermal compounds, heat sinks, and phase-change materials that maximize heat dissipation, prolonging device lifespan and enhancing performance.

Surface Treatment and Coating: Electronic components often require protective coatings against oxidation, moisture, and dust. I recommend coatings that prevent corrosion without impacting electrical conductivity or causing heat retention.

Adhesives and Sealants: With miniaturization trends, choosing adhesives that can securely bond delicate parts without compromising heat dissipation or durability is crucial. I help clients identify and apply high-performance adhesives and sealants designed for electronics.

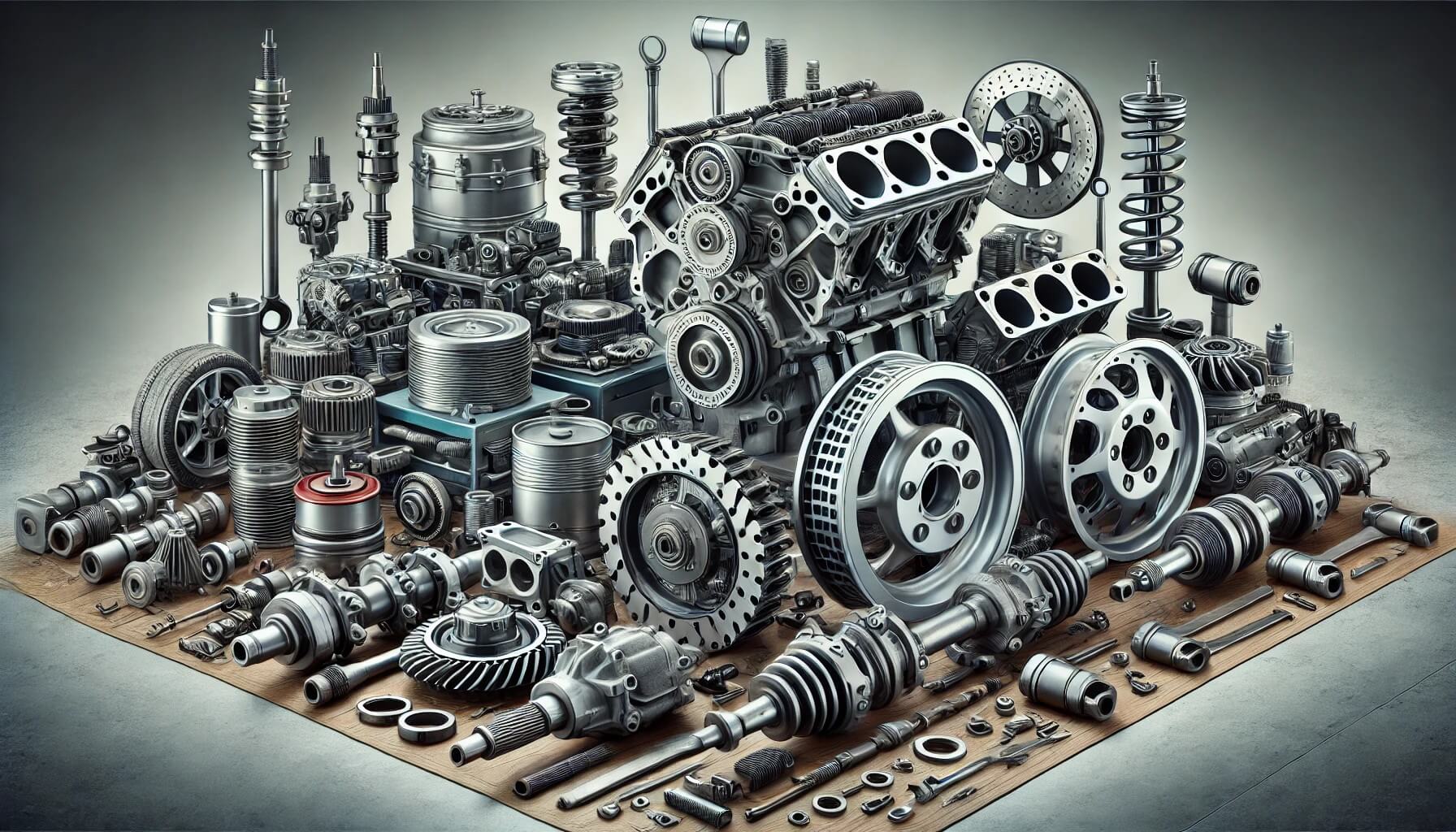

2. Automotive and Aerospace Industry

Metalworking Fluids and Lubricants: Manufacturing processes such as drilling, milling, and cutting require specialized fluids to minimize wear and tear on machinery and ensure smooth operations. I help clients choose fluids that enhance efficiency while minimizing residue and environmental impact.

Rust and Corrosion Management: Automotive and aerospace components are often exposed to harsh conditions. I provide solutions for corrosion protection in transit, storage, and operation, including rust-preventive coatings, anti-corrosive lubricants, and sacrificial coatings.

Thermal Insulation and Sound Dampening: In high-performance applications, managing heat and noise is critical. I recommend materials with excellent thermal and acoustic insulation properties, improving passenger comfort and operational safety.

3. Heavy Equipment and Machinery Industry

Surface Protection and Coating: Heavy machinery requires robust surface treatments to withstand tough conditions such as abrasion, impact, and moisture exposure. I assist in selecting coatings that offer durable protection against rust, UV radiation, and chemical exposure.

Hydrotesting and Rust Prevention: For equipment manufacturers, hydrotesting is essential to ensure strength and safety. I provide recommendations on anti-corrosion agents and rust inhibitors that protect metals from water-induced corrosion during testing and storage.

Heat Transfer Solutions: In machinery operations where heat generation is significant, I advise on thermal fluids and heat transfer compounds that improve cooling efficiency without causing equipment degradation.

4. Construction and Infrastructure

Concrete and Surface Treatments: Construction materials require surface treatments to protect against environmental factors. I provide guidance on sealants and coatings that prevent water infiltration, UV damage, and microbial growth, extending the lifespan of infrastructure.

Protective Coatings for Metals: Structural components are exposed to varying climates and require protection against rust and corrosion. I help select protective coatings and corrosion inhibitors to keep metals robust and resilient over time.

Sound and Vibration Control: In buildings and structures, soundproofing and vibration control improve comfort and safety. I suggest materials and solutions that mitigate noise and vibration transmission effectively.

5. Food Processing and Packaging

Food-Grade Lubricants and Cleaners: Food processing equipment requires safe and non-toxic lubricants to ensure smooth operations without contamination risks. I recommend lubricants and cleaners compliant with food safety standards, helping maintain a clean and safe production environment.

Temporary Surface Protection: Packaging lines often need temporary surface protection solutions to prevent damage during transport. I help select surface protectants that are effective yet easy to remove, ensuring that packaging quality is maintained.

Anti-Corrosive Coatings: Moist environments in food processing facilities can lead to equipment corrosion. I offer corrosion protection solutions, such as specialized coatings, to prolong equipment life and maintain hygiene standards.

6. Textile and Apparel Industry

Food-Grade Lubricants and Cleaners: Food processing equipment requires safe and non-toxic lubricants to ensure smooth operations without contamination risks. I recommend lubricants and cleaners compliant with food safety standards, helping maintain a clean and safe production environment.

Temporary Surface Protection: Packaging lines often need temporary surface protection solutions to prevent damage during transport. I help select surface protectants that are effective yet easy to remove, ensuring that packaging quality is maintained.

Thermal Insulation: Textiles used in outerwear or insulation require materials that retain heat efficiently. I help identify thermal management solutions for textiles to ensure comfort and energy efficiency in various climates.

7. Pharmaceutical and Medical Devices

Biocompatible Coatings and Lubricants: Medical devices must adhere to strict biocompatibility standards. I guide companies in selecting coatings and lubricants that meet these standards without introducing toxins.

Chemical Stability: Pharmaceuticals and devices often require containers or packaging with high chemical resistance. I assist in selecting materials that ensure stability and efficacy, minimizing contamination risks.

Thermal Management: Devices like MRI machines generate significant heat and require efficient cooling. I advise on cooling solutions that ensure safe, consistent temperatures without compromising device performance or patient safety.

8. Renewable Energy and Power Generation

Heat Transfer and Thermal Compounds: Solar panels, wind turbines, and energy storage systems generate substantial heat during operation. I recommend thermal management solutions that increase efficiency and protect equipment from overheating.

Corrosion Protection in Offshore Applications: Offshore wind turbines and solar installations are constantly exposed to saltwater and moisture. I offer anti-corrosive coatings and rust inhibitors to protect these investments.

Adhesives and Bonding Solutions: Renewable energy installations need durable adhesives for panel mounting and component assembly. I assist in selecting adhesives that are resilient under extreme temperatures and environmental conditions.

9. Consumer Goods and Appliances

Thermal Insulation and Heat Management: Appliances such as refrigerators, ovens, and washing machines produce heat that requires management. I guide manufacturers in choosing thermal insulation and heat transfer solutions that enhance efficiency and safety.

Anti-Rust and Protective Coatings: Appliances are often subject to moisture and chemicals, leading to corrosion. I recommend protective coatings that prolong lifespan and maintain product aesthetics.

Noise and Vibration Reduction: Reducing noise and vibration in appliances enhances user comfort. I advise on soundproofing materials and vibration-dampening technologies to improve appliance performance.

10. Automotive and Industrial Coatings

Corrosion Resistance: Automotive parts are exposed to various environmental factors that can lead to corrosion. I provide rust-resistant coatings for engine parts, underbody components, and exposed surfaces.

Metalworking Fluids for Efficiency: For parts manufacturing, metalworking fluids are essential for cutting, shaping, and grinding. I help select fluids that improve the quality of machining processes and extend tool life.

Surface Finishing and Temporary Protection: Industrial and automotive components may require temporary protection during assembly and transport. I suggest temporary coatings that protect surfaces from scratches and corrosion.